QUALIFICATION OF THE PERSONNEL RESPONSIBLE FOR CARRYING OUT NON-DESTRUCTIVE TESTS (NDT) IN THE INDUSTRIAL SECTOR RAILWAY, AERONAUTICAL AND CIVIL, ON MATERIALS AND WELDED JOINTS

Filippo Centineo's RINAS welding school, in collaboration with TUVAUSTRIAITALIA, organizes training courses for Non-Destructive Welding Tests, in compliance with EN ISO 9712:2012.

Non-destructive testing (NDT) is a complex of examinations, checks and measurements conducted using methods that do not alter the material and do not require the destruction or removal of specimens from the structure under examination.

The fundamental characteristic of this type of test is being able to verify the details under examination without interfering with the material under test. Non-Destructive Testing is a fundamental tool for the final control of the product, ensuring its compliance with the project requirements.

Contact us to request a free, no-obligation quote or to make an appointment with the secretariat.

REGISTRATIONS ARE OPEN

FOR THE NON-DESTRUCTIVE TESTS OPERATORS COURSE

(#VT, #PT, #MT)

-

Level 2

Methods:

VT Visual Examination PT Liquid Penetrant MT Magnetoscopic Control

From 13 to 24 May 2024

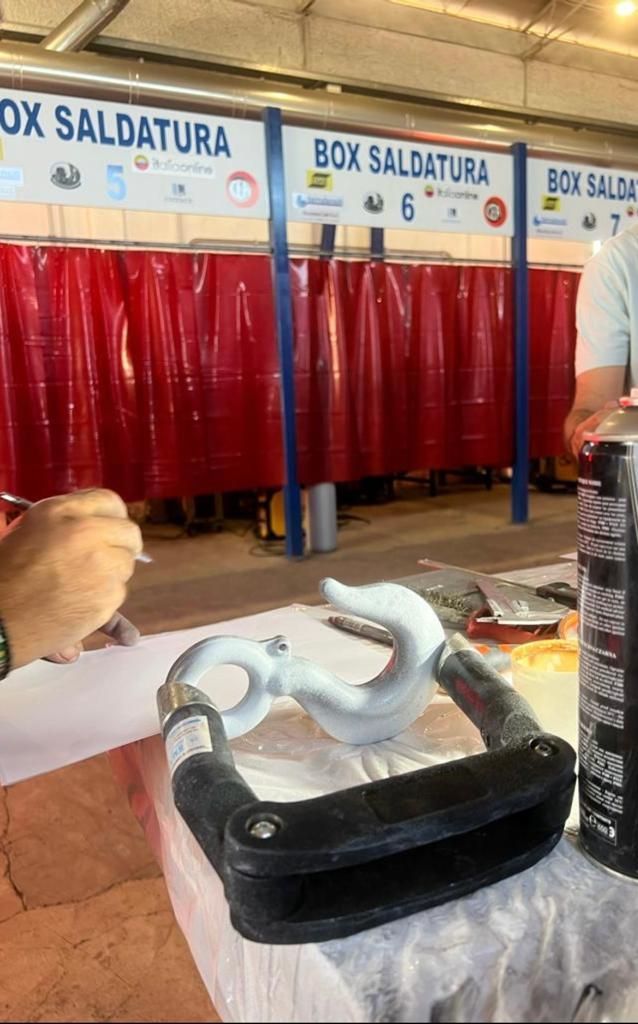

Location: Rinas welding school Bagheria (PA) Sicily

At the end of the lessons, participants will be able to take the exam for UNI EN #ISO9712 certification.

The Tuv Austria Italy certification body

For info contact us or write to scuolasaldaturarinas.com

THE OBJECTIVES OF THE COURSE ARE:

Provide the candidate with the technical/regulatory knowledge necessary to carry out Visual, Liquid Penetrant and Magnetoscopic inspections on various types of materials, semi-finished and finished products and in particular in compliance with established or recognized procedures:

- Select the NDT technique for the test method to be used;

- Define the application limits of the test method;

- Draft NC instructions;

- Carry out and supervise all Level 1 duties;

- Provide assistance to staff at level 2 or lower;

- Organize and write CND reports.

RECIPIENTS

Designers, Quality Offices, Testing Technicians

DURATION:

The course has a total duration of 40 hours, divided into two modules 2 days (16 hours) and 3 days (24 hours).

CONTENTS OF THE NDT CONTROL OPERATOR COURSE

- Notes on metallurgy;

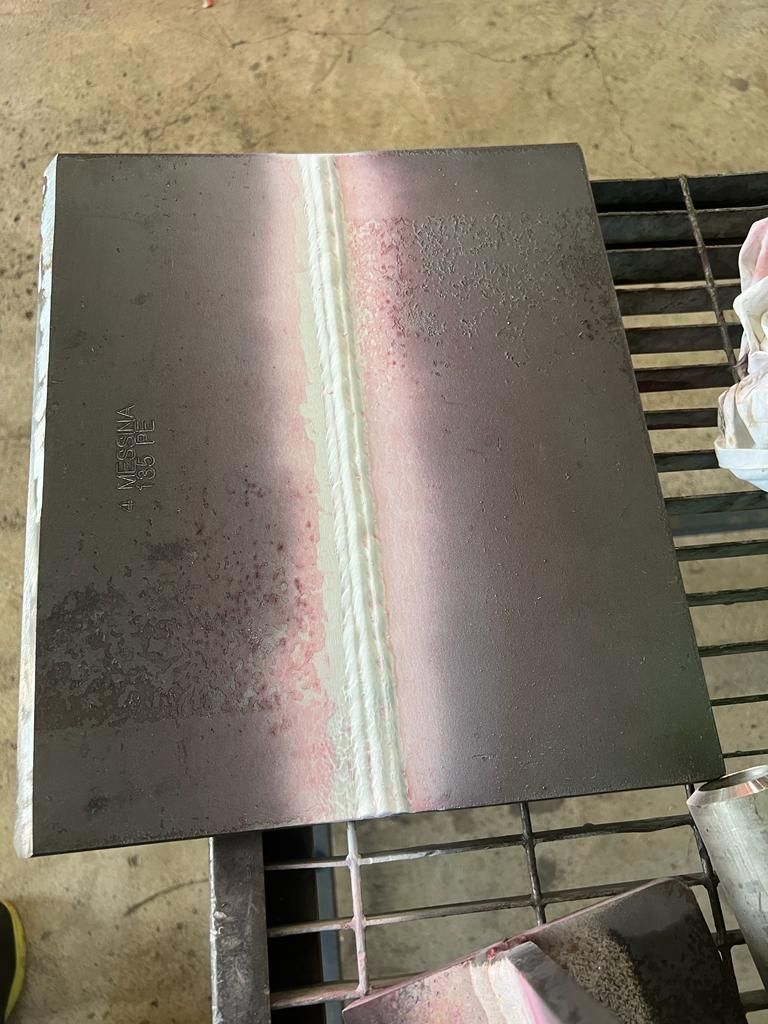

- Welding defects;

- Defectology of welded joints with reference to UNI EN ISO 5817 and UNI EN ISO 10042;

- Defectology of semi-finished products (castings, rolled, forged, pressed, tubes, sheets, etc.);

- Notes on operational defects;

- Practical control exercises;

VT – Inspection

Visual

Observation/measurement carried out visually with the naked eye or with auxiliary devices, of the object

Examination.

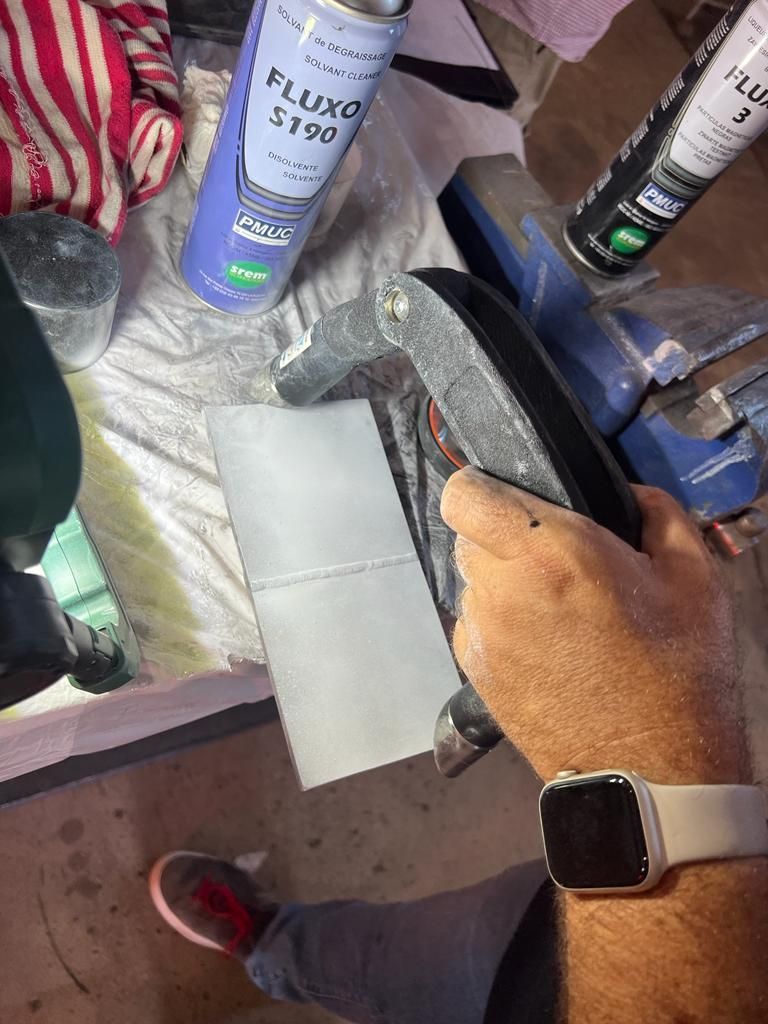

PT – Liquids Penetrating

Enhancement of the visibility of open surface defects through the use of a liquid substance that penetrates the defects by capillarity (penetrant) and a background (detector or the piece

MT – Control

Magnetoscopic

Attraction of ferromagnetic particles (and dispersed in liquid) attracted by the magnetic field dispersed near any cracks.

At the end of the lessons, participants will be able to take the certification exam

UNI EN ISO 9712 with an accredited body TÜV AUSTRIA ITALY